In moment’s presto- paced manufacturing world, motor assembly lines are evolving to meet the demands for increased productivity and quality. The motor assembly line plays a pivotal part in icing effective product processes, particularly in diligence similar as automotive, electronics, and ménage appliances. With the nonstop advancement in technology, manufacturers are espousing high- speed results that reduce product time, enhance affair, and streamline operations.

Assembly in Modern Manufacturing

Motor assembly lines have come an integral part of manufacturing, especially with the growing demand for high- performance motors used in colorful operations. These lines are designed to streamline the product of motors, icing that each element is precisely assembled, tested, and packaged. Whether it’s a DC motor winding machine or a small motor winding machine, the motor assembly line is equipped with perfection ministry that ensures the delicacy and effectiveness needed for ultramodern product requirements.

DC Motor Winding Machines

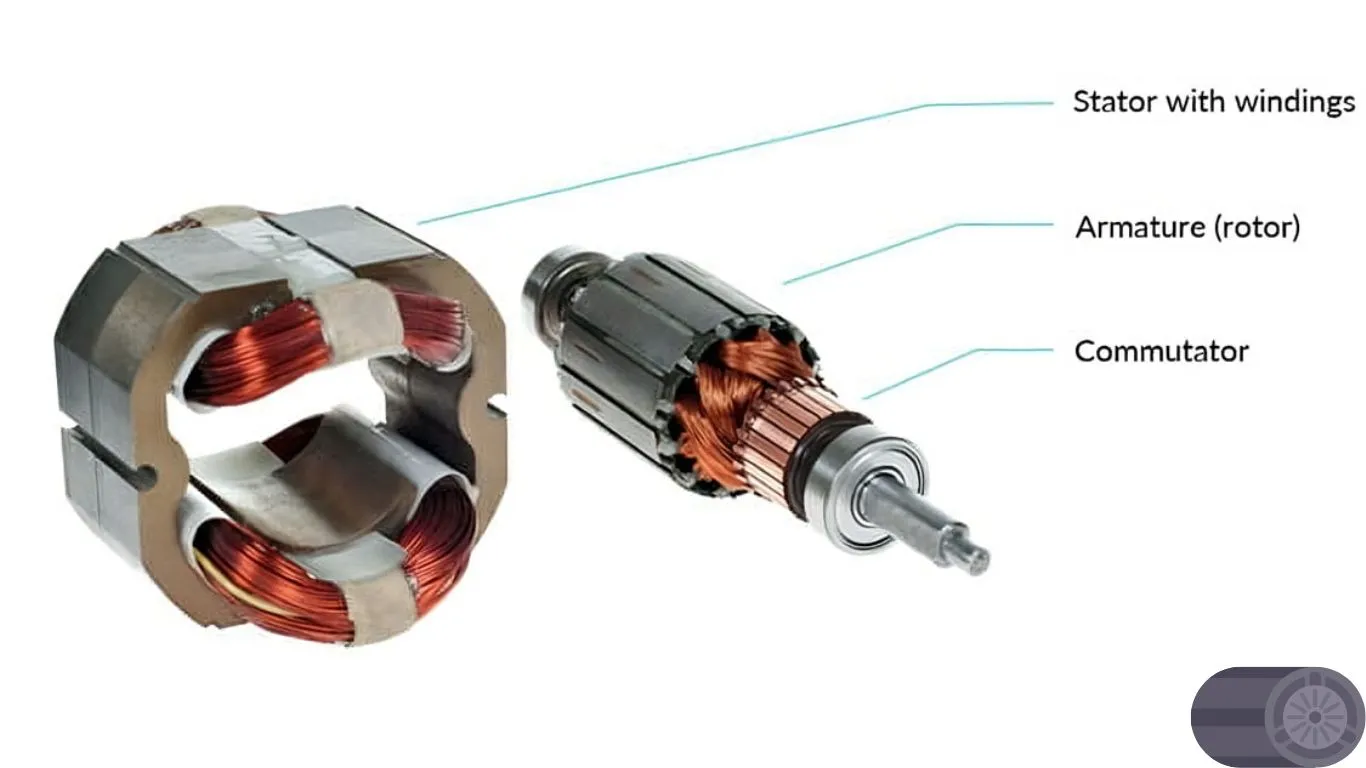

The DC motor winding machine plays a vital part in the motor assembly process, especially for the product of DC motors, which are generally used in automotive, robotics, and artificial operations. These machines are designed to automate the winding process, icing that the coils are tightly wound with perfection and delicacy. The integration of DC motor winding machines into assembly lines has significantly bettered product pets, reducing the need for homemade labor and minimizing mortal error.

The perfection of DC motor winding machines also allows for better motor performance and continuity, as the coils are slightly wound. This not only enhances the effectiveness of the final product but also helps manufacturers achieve advanced- quality norms that are essential for staying competitive in moment’s request.

Small Motor Winding Machines

Another crucial element in the motor assembly line is the small motor winding machine, which is used to produce compact motors for a variety of diligence. These machines are specifically designed to handle the product of lower motors, which are essential for operations in consumer electronics, power tools, and medical bias. Small motor winding machines offer manufacturers the inflexibility to produce a wide range of motor sizes and types, all while maintaining high effectiveness and low product costs.

With the growing demand for compact, high- performance motors, small motor winding machines have come necessary in the ultramodern assembly line. These machines are finagled to handle intricate winding processes with great perfection, making them ideal for diligence where size and performance are consummate.

Crucial motorists of effectiveness

One of the most significant advancements in motor assembly lines is the integration of robotization technology. Automated systems help ameliorate the speed and delicacy of product, allowing for lesser outturn with lower mortal intervention. Machines similar as the DC motor winding machine and small motor winding machine can be operated with minimum supervision, significantly adding the product speed and reducing the threat of crimes.

Automated motor assembly lines are able of performing multiple tasks contemporaneously, similar as winding, testing, and packaging, all within a bit of the time it would take for homemade processes. As a result, manufacturers can meet the ever- growing demand for motors while keeping product costs low and maintaining high- quality norms.

Performance and trustability

In motor assembly, quality control is essential to insure that the final product meets the needed performance norms. As motor assembly lines incorporate high- speed machines like DC motor winding machines and small motor winding machines, manufacturers are also enforcing advanced testing systems to cover the quality of each motor. These testing systems are designed to estimate the motor’s performance, similar as its speed, necklace, and power consumption, to insure it meets assiduity norms.

Advanced testing outfit is integrated into the assembly line, enabling manufacturers to perform real- time checks on each motor. This ensures that only motors that pass strict quality control measures are transferred for packaging, significantly reducing the chances of imperfect products reaching the request.

Assembly results

For manufacturers looking to upgrade their motor assembly lines with high- speed results, companies like. honest automation offer state- of- the- art machines and outfit. Specializing in DC motor winding machines and small motor winding machines,honest automation provides acclimatized results that meet the specific requirements of manufacturers in colorful diligence. Their products are designed for maximum effectiveness, trustability, and performance, icing that manufacturers can stay competitive in the fast- paced global request.

Honest- HLS is committed to furnishing slice- edge technologies that ameliorate motor assembly lines, enhancing the overall effectiveness of the product process. With a focus on quality and-hls.com is helping manufacturers meet the growing demands for high- performance motors while maintaining sustainable practices.

Employing the Power of honest automation for Assiduity Growth

Honest automation is revolutionizing diligence by furnishing transparent and effective results that foster trust and productivity. Unlike traditional systems, honest automation prioritizes ethical norms, icing that automated processes align with organizational values and societal prospects. This approach not only streamlines operations but also builds long- term credibility, making it an inestimable asset for businesses aiming to thrive in competitive requests. By using honest automation, companies can achieve harmonious results while maintaining translucency in their processes, eventually enhancing stakeholder confidence and satisfaction.

honest automation A New period of Ethical Innovation

The integration of honest automation into ultramodern workflows represents a significant vault toward ethical invention. This conception emphasizes fairness, responsibility, and delicacy in automated systems, icing that technology serves humanity without compromising integrity. honest automation enables associations to reduce mortal error, ameliorate decision- timber, and foster inclusivity by addressing impulses essential in traditional systems. As diligence evolve, espousing honest automation is n’t just a trend but a necessity for sustainable growth and ethical leadership in the digital age.

FAQs on Motor Assembly Lines

1. What’s a motor assembly line?

A motor assembly line is a product system where motors are efficiently assembled using automated ministry to streamline the process and insure high- quality affair.

2. What’s a DC motor winding machine?

A DC motor winding machine automates the process of winding bobby coils around a motor’s architecture, icing precise and harmonious windings for DC motors.

What’s a small motor winding machine?

A small motor winding machine is designed to wind coils for compact motors, generally used in consumer electronics, power tools, and medical bias.

Conclusion

The future of motor assembly lines lies in the continued development of high-speed, automated results that streamline products and ensure high- quality labor. With the integration of machines like DC motor winding machines and small motor winding machine, manufacturers are suitable to meet the ever-adding demand for motors while keeping costs low and quality high. As technology continues to advance, the motor assembly line will evolve, embracing new inventions that will further ameliorate effectiveness, performance, and sustainability in the manufacturing assiduity.

Backlinks Hub highly experienced SEO Team with over 4 years of experience. WE are working as contributors on 100+ reputable blog sites. If You Need Guest Post and Our Seo Services Contact Email: backlinkshubs@gmail.com And Visit Our Website: http://backlinkshub.uk/